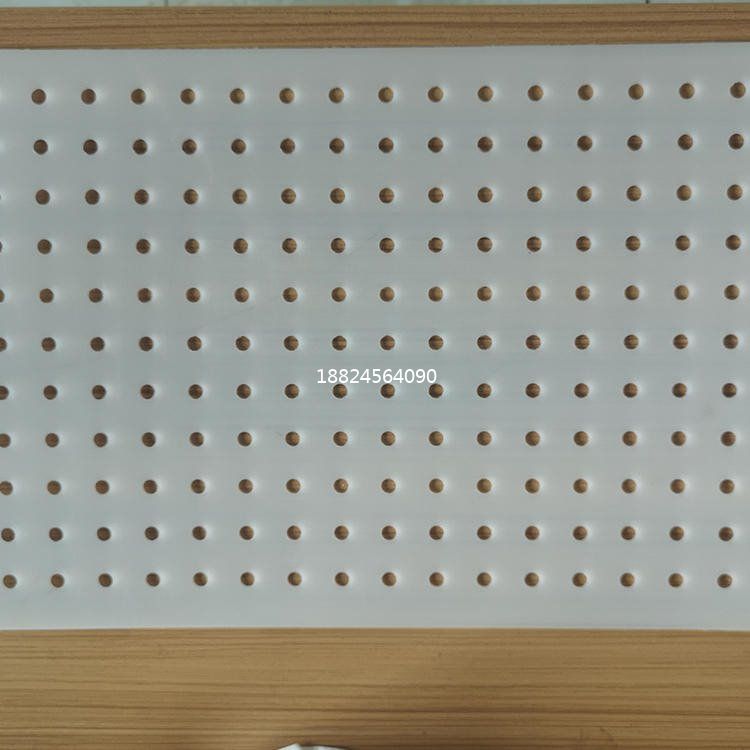

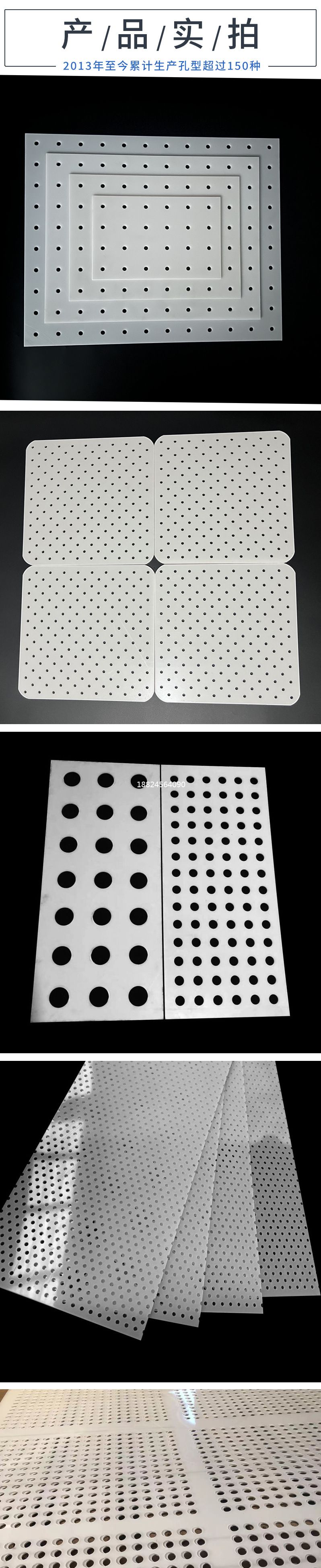

Perforated plastic sheet,PP sheet with hole,PP sheet with punched holes

1. **Material:** Plastic perforated sheets are typically made from thermoplastic polymers such as PP, PE, or PVC, chosen for their durability, lightweight nature, and resistance to corrosion and chemicals.

2. **Perforation Patterns:** The perforations can be customized to suit specific requirements. Common patterns include staggered round holes, square holes, slotted holes, or decorative patterns. The diameter or size of the holes can range from very small to larger openings.

3. **Applications:** Plastic perforated sheets have diverse applications across various industries:

- **Filtration:** Used in air filtration systems, water filtration, and industrial sieving applications.

- **Acoustic Panels:** Helps in sound absorption and noise reduction when used in acoustic panels or enclosures.

- **Ventilation:** Facilitates airflow while providing protection against debris or pests.

- **Decorative Panels:** Used for architectural and design purposes in interior and exterior decoration.

- **Protective Shields:** Acts as protective barriers in machinery or equipment.

- **Light Diffusion:** Used in lighting fixtures to diffuse light evenly.

4. **Advantages:**

- **Lightweight:** Easy to handle and install.

- **Chemical Resistance:** Resistant to corrosion and chemicals, making them suitable for harsh environments.

- **Customizable:** Can be tailored to specific requirements in terms of hole size, pattern, and sheet thickness.

- **Durable:** Offers good durability and weather resistance.

5. **Color and Finish:** Plastic perforated sheets are available in various colors and finishes, including opaque, translucent, or tinted options, to suit aesthetic preferences and functional needs.

6. **Installation:** The sheets can be cut, shaped, or fabricated easily using standard tools for installation in different applications.